Imagine you’re transported back in time, surrounded by lush green forests and the sound of rushing water. You stumble upon a river, and the idea strikes you: why not build a water wheel? In this article, we will guide you through the process of creating a primitive water wheel from scratch. Get ready to channel your inner engineer and embark on a fascinating journey into the past as you learn how to harness the power of nature to create a functional and charming water wheel.

Materials and Tools

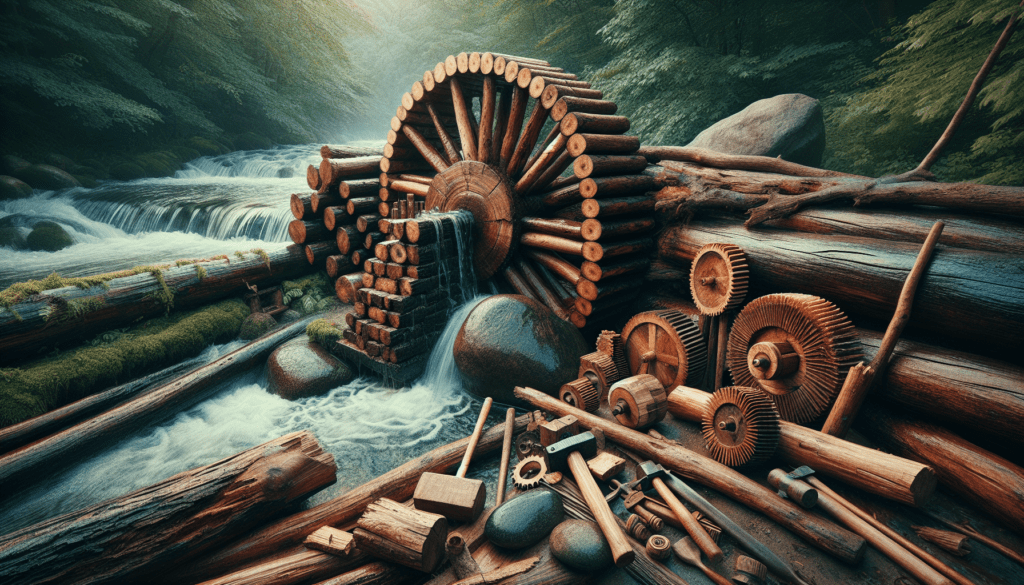

To build a primitive water wheel, you will need a few key materials and tools. Here is a list of what you’ll need:

Wood

First and foremost, you’ll need some wood for constructing the water wheel. Depending on the size and design of the wheel, you may require different types of wood. It is recommended to use sturdy, weather-resistant wood like cedar or oak.

Nails or screws

Choose either nails or screws to secure the different components of the water wheel together. Nails are traditional and reliable, while screws provide added strength and durability.

Hammer or screwdriver

A hammer is essential if you opt for nails, while a screwdriver will be needed if you choose screws. Make sure to have the appropriate tool on hand to facilitate the construction process.

Saw

A saw is necessary to cut the wooden components of the water wheel to the desired size and shape. A handsaw or a circular saw can both work well for this purpose.

Drill

A drill will come in handy for creating holes in the wood when assembling the water wheel. You’ll need it for tasks such as attaching the spokes to the wheel rim and installing the axle supports.

Measuring tape

Accurate measurements are crucial when building a water wheel, as they ensure the components fit together properly. Use a measuring tape to take precise measurements before cutting the wood.

Pencil

A pencil is required for marking the wood before making any cuts or drilling holes. It allows you to create clear guidelines and ensures accuracy during construction.

Now that you have gathered all the necessary materials and tools, let’s move on to the next step: choosing the right location for your water wheel.

Choosing the Right Location

When deciding where to place your primitive water wheel, there are a few factors to consider to ensure optimal performance and ease of use. Here are some key aspects to keep in mind:

Water source

The water wheel relies on a constant flow of water to function effectively. Therefore, choose a location near a reliable water source, such as a river or stream. The water should have sufficient depth and velocity to power the wheel.

Level ground

Ensure that the ground where you plan to install the water wheel is level. A level surface is essential for the stability and proper operation of the wheel. If the ground is uneven, you may need to create a leveled base using gravel or concrete.

Access to the wheel

Make sure there is enough space around the water wheel for easy access. This will allow you to perform maintenance, make adjustments, and monitor its performance without any hindrances. Additionally, consider building a pathway or access ramp to reach the wheel conveniently.

Taking these factors into account will help you select the most suitable location for your water wheel. Once you have determined the ideal spot, it’s time to move on to designing the water wheel itself.

Designing the Water Wheel

Before you start building the water wheel, it’s important to consider its design. Here are a few key factors to think about:

Determining the wheel size

The size of your water wheel will depend on various factors, including the available space, the amount of water available, and the intended purpose of the wheel. A larger wheel will generally produce more power but will require a greater water flow.

Number of buckets

The number of buckets on the wheel will affect its efficiency and power output. More buckets can capture more water, but too many buckets may increase friction and slow down the wheel. A suitable number of buckets is typically between 6 and 12.

Bucket shape

The shape of the buckets is crucial for efficient water capture and release. The best bucket shape is generally rectangular or slightly tapered, allowing the water to flow smoothly. Avoid overly complex designs that may hinder the wheel’s performance.

Axle and bearings

The axle is a critical component that enables the wheel to rotate smoothly. It should be sturdy enough to withstand the weight of the wheel and any external forces. Bearings should be installed to reduce friction and ensure the axle spins freely.

By carefully considering these design elements, you can create a water wheel that fits your specific needs and optimizes its performance. With the design in mind, let’s move on to the next step: preparing the wood.

Preparing the Wood

Before assembling the water wheel, it is essential to prepare the wood to ensure durability and longevity. Follow these steps to get your wood ready:

Cutting the wheel components

Using the measurements you determined during the design phase, use a saw to cut the necessary wooden components for the wheel, such as the spokes, rim, and bucket pieces. Make sure the cuts are clean and accurate for proper assembly.

Sand and smooth the surfaces

Once the components are cut, sand the surfaces of the wood to remove any rough edges or splinters. This step not only improves the appearance but also prevents potential injuries during construction and maintenance.

Applying wood preservative

To protect the wood from rotting and damage caused by exposure to water, apply a wood preservative to all the surfaces. This will extend the lifespan of your water wheel and ensure it remains in good condition over time.

With the wood properly prepared, you can now begin constructing the main frame of the water wheel.

Constructing the Main Frame

The main frame of the water wheel provides stability and support for the rotating wheel. Follow these steps to build the main frame:

Building the base

Start by constructing a sturdy and level base for the water wheel. This can be done using beams or planks of wood linked together to form a solid foundation. Ensure that the base is large enough to accommodate the wheel’s size and provide ample stability.

Attaching the upright supports

Next, attach upright supports to the base to provide additional stability for the wheel. These supports should be spaced evenly around the circumference of the wheel, providing enough strength to handle the weight and forces exerted during operation.

Installing the axle supports

Install the axle supports on both sides of the base. These supports will hold the axle in place and prevent it from shifting during rotation. Make sure the supports are aligned properly and firmly attached to avoid any wobbling.

With the main frame constructed, it’s time to move on to building the wheel components.

Building the Wheel Components

The wheel components are crucial for the functionality and rotation of the water wheel. Follow these steps to build the wheel:

Cutting and shaping the wheel spokes

Using the measurements and design specifications, cut and shape the wheel spokes from the prepared wood. The spokes should be strong and evenly sized to ensure balanced rotation. Use a saw and drill to create the necessary holes for attaching the spokes to the wheel rim.

Building the wheel rim

Construct the wheel rim by connecting wooden planks or beams to form a circular structure. Ensure that the rim is precisely sized to fit the spokes and allow enough space for the buckets to be attached securely.

Attaching the spokes to the rim

Using nails or screws, attach the spokes to the wheel rim. Make sure they are evenly spaced around the rim and firmly secured, as they will bear the weight of the buckets and spin as the water wheel operates.

With the wheel components assembled, it’s time to focus on creating the buckets.

Creating the Buckets

The buckets on the water wheel play a crucial role in capturing and releasing water, generating rotational energy in the process. Follow these steps to create the buckets:

Cutting the bucket pieces

Using the design specifications, cut the bucket pieces from the prepared wood. Ensure that the dimensions are accurate, as the buckets need to fit securely onto the wheel spokes.

Shaping the buckets

Shape the bucket pieces according to the desired design, such as rectangular or slightly tapered shapes. Use a saw and sandpaper to create smooth edges and surfaces that will allow water to flow freely.

Attaching the buckets to the wheel

Using nails or screws, attach the buckets securely to the wheel spokes. Make sure they are evenly spaced and aligned for optimum water capture and release. Test the rotation of the wheel to ensure all the buckets move smoothly without obstruction.

With the buckets in place, it’s time to mount the wheel onto the axle.

Mounting the Wheel

Mounting the wheel onto the axle is a critical step in the construction process. Follow these steps to properly install the wheel:

Installing axle and bearings

Place the axle between the axle supports, ensuring that it is level and securely positioned. Insert bearings on each end of the axle to reduce friction and allow smooth rotation. Ensure that the axle is centered and perpendicular to the water wheel.

Attaching the wheel to the axle

Using screws or nails, attach the wheel to the axle. Make sure it is securely fastened and spins freely without any obstructions. Test the rotation and stability of the wheel to ensure it moves smoothly and effortlessly.

With the wheel securely mounted, it’s time to prepare the water flow for its operation.

Preparing the Water Flow

To optimize the performance of your water wheel, it is necessary to create a suitable water flow. Follow these steps to prepare the water flow:

Creating a water channel

Construct a channel or trough that leads the water towards the wheel. Ensure that the channel is wide enough and properly aligned with the buckets to achieve maximum efficiency. The water should flow steadily and directly onto the buckets.

Adjusting the water flow

Experiment with different water flow rates by adjusting the channel’s width or installing gates or barriers. Find the optimal balance between water input and output to achieve the desired rotational speed and power output from your water wheel.

Now that your water wheel is in operation, it’s essential to perform regular maintenance to keep it functioning at its best.

Maintenance and Upkeep

To ensure the longevity and efficiency of your water wheel, regular maintenance and upkeep are necessary. Here are a few steps to follow:

Cleaning the wheel

Periodically clean the wheel and remove any debris or sediment that may accumulate in the buckets or on the spokes. This will prevent any obstruction to the water flow and ensure smooth operation.

Checking for wear and tear

Regularly inspect the various components of the water wheel, such as the spokes, rim, and buckets, for signs of wear and tear. Replace any damaged or weakened parts to maintain the wheel’s structural integrity and functionality.

Regular lubrication

Apply lubricant to the axle and bearings to reduce friction and ensure smooth rotation. This will prolong the lifespan of these crucial components and prevent any unnecessary strain on the wheel.

By following these maintenance practices, you can ensure that your primitive water wheel continues to operate efficiently and effectively over time.

In conclusion, constructing a primitive water wheel can be a rewarding and enjoyable project. By carefully selecting the materials, designing the wheel, and preparing the wood components, you can create a functional and efficient water wheel. With proper installation, water flow, and maintenance, your water wheel will provide a renewable source of power for various applications. So, gather your materials, pick the right location, and start building your very own primitive water wheel today!